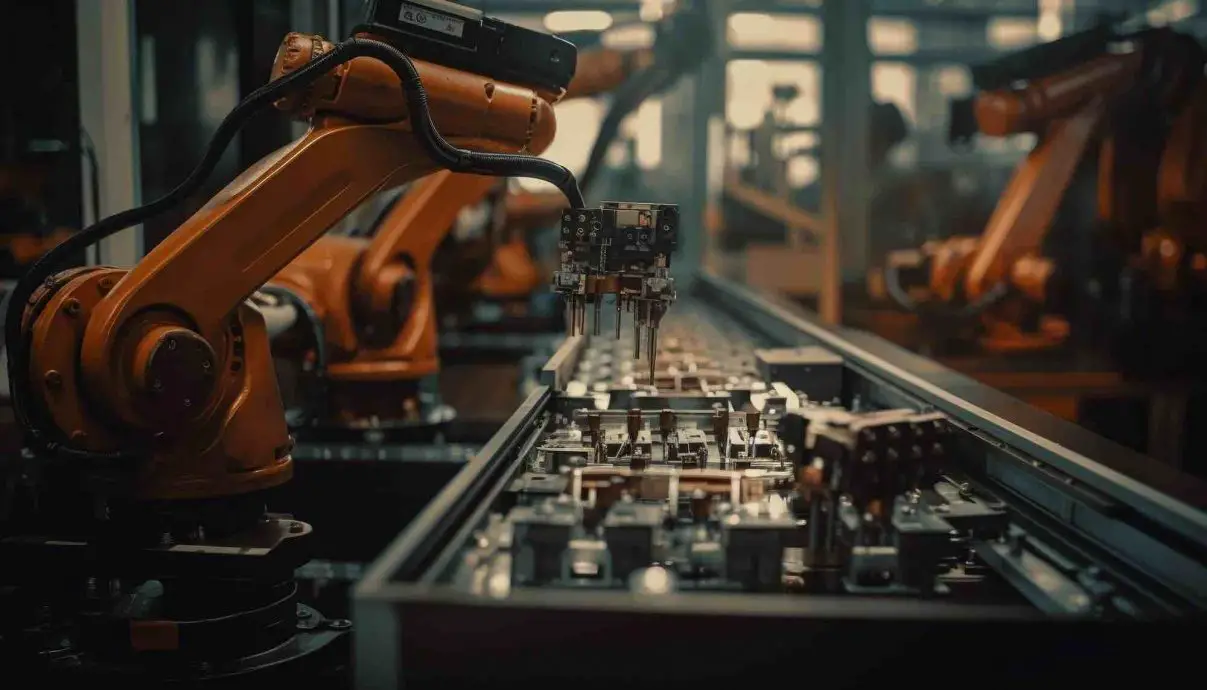

What are Pick and Place Robots?

Pick and place robots, the tireless maestros of precision movement, are revolutionizing industries from electronics assembly to pharmaceuticals. But beyond their impressive dexterity, a fascinating world of technology and evolution unfolds. Let’s dive into the diverse types, rich history, and cutting-edge AI integration that power these robotic marvels.

Pick and place robots represent a specialized category within industrial robotics, primarily focused on material handling. These robots are designed for precision. They move objects with high accuracy and speed, transferring them from one location to another. This technology plays a pivotal role in streamlining and optimizing various processes in manufacturing and packaging industries.

Also Read: AI Hardware Faces Critical Turning Point

Table of contents

- What are Pick and Place Robots?

- The Operational Mechanics Behind Pick and Place Robots

- Key Components in Pick and Place Robotics

- Classifications of Pick and Place Robots

- Enhancing Efficiency: The Benefits of Utilizing Pick and Place Robots

- Real-World Applications: Where Pick and Place Robots Shine

- Sector-Specific Utilization of Pick and Place Robots

- Selecting the Optimal Pick and Place Robot for Your Operational Needs

- Investment Analysis: Understanding the Cost of Pick and Place Robots

- Task Spectrum: The Versatility of Pick and Place Robots in Action

- Future Directions in Pick and Place Robotics: Trends and Innovations

- Conclusions: Summarizing the Impact and Potential of Pick and Place Robots

- AI-Powered Intelligence: Amplifying Robotic Capabilities:

- Addressing Common Queries Regarding Pick and Place Robots

- References and Further Reading

Definition and Basic Understanding of Pick and Place Robots

An automated machine, known as a pick and place robot, features a robotic arm and an end-effector – either a gripper or a vacuum system – for handling objects. Software controls these robots, which often integrate with sensors and vision systems for enhanced operation. Their primary function is to pick up parts, components, or products from one place and accurately place them in another, predetermined location. This simple yet critical task is key to automating repetitive and labor-intensive processes in industrial settings.

Primary Functions and Roles in Industrial Automation

Pick and place robots are invaluable in various aspects of industrial automation:

- Efficiency in Production Lines: They significantly enhance the speed of production processes, enabling faster handling and placement of components or products.

- Accuracy and Consistency: By executing tasks with high precision, these robots minimize errors, ensuring consistent quality in manufacturing.

- Reduction of Manual Labor: Automating repetitive tasks reduces the physical strain on human workers and decreases the likelihood of errors due to fatigue.

- Adaptability: Modern pick and place robots are adaptable to a range of tasks. They handle different materials and products and can be reprogrammed for various tasks. This versatility makes them valuable assets in manufacturing.

- Safe Operation: These robots can handle hazardous environments. They can deal with hot, heavy, or toxic materials, improving workplace safety.

Evolution of Pick and Place Robots

Historical Development

The history of pick and place robots is a story of gradual evolution paralleling technological advances. In their earliest forms, these robots were mechanical arms. They had limited capabilities and were used for simple tasks on assembly lines. The 1960s and 1970s marked a major leap with programmable robots. These robots brought increased versatility and control.

A Historical Trajectory: From Crude Beginnings to Refined Elegance:

Early Prototypes (1950s-1960s): The seeds of pick and place technology were sown in the 1950s with rudimentary hydraulic and pneumatic robots. These lacked programmability and finesse, but laid the groundwork for future advancements.

Industrial Rise (1970s-1990s): The introduction of electric servo motors and programmable controllers in the 1970s ushered in a new era of precision and control. Pick and place robots found their footing in industries like automotive and electronics manufacturing.

The AI Revolution (2000s-Present): The 21st century witnessed the integration of artificial intelligence and machine learning into pick and place robots. Vision systems enable these robots to identify and grasp objects with remarkable accuracy, even in cluttered environments.

Technological Advancements and Their Impacts

The capabilities of pick and place robots have expanded dramatically in recent years due to several key technological advancements:

- Advanced Vision Systems: Integration of sophisticated vision systems has allowed robots to identify and orient objects of various shapes, sizes, and orientations. This technology is crucial in industries where precision is paramount, such as electronics manufacturing, where components are small and delicate.

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning algorithms have been incorporated. They enable robots to optimize paths and movements, reducing cycle times and increasing productivity. These advancements also allow robots to adapt to new tasks with minimal programming. This makes them more flexible and easier to integrate into different production lines.

- Collaborative Robotics (Cobots): The emergence of cobots has been a significant development. Cobots, unlike traditional industrial robots, are designed to work alongside human workers. They complement human capabilities and enhance productivity. Cobots are typically smaller, more versatile, and equipped with safety features, making them suitable for a wider range of applications, including small-scale operations.

- Miniaturization and Cost Reduction: Technological advancements have led to component miniaturization. This makes pick and place robots more compact and less expensive. As a result, robotic automation is accessible to smaller businesses that couldn’t afford or accommodate traditional industrial robots before.

The evolution of pick and place robots mirrors broader automation and technology trends. It’s moving toward more intelligent, versatile, and accessible robotic systems. This evolution enhances operational efficiencies in manufacturing and packaging. It also opens new possibilities for automation in various sectors.

Also Read: Top AI Robotics Stocks Set for Growth

The Operational Mechanics Behind Pick and Place Robots

Basic Principles of Operation

Pick and place robots operate on fundamental concepts that allow them to perform precise and repetitive tasks efficiently. The basic operation of these robots involves four primary stages: identification, picking, transporting, and placing.

- Identification: The robot identifies the object to be picked. This often involves advanced vision systems that scan and recognize objects based on size, shape, color, or barcode.

- Picking: Once identified, the robot uses its end-effector, which can be a gripper or a vacuum system, to securely grasp the object. The design of the end-effector varies depending on the nature of the objects being handled.

- Transporting: After picking the object, the robot moves it from its original location to a new predetermined location. This movement is carried out with precision to ensure the object is not damaged.

- Placing: The final stage involves the robot placing the object at the designated spot, which could be a conveyor belt, a packaging container, or an assembly line.

Workflow of a Typical Pick and Place Robot

A pre-programmed sequence typically governs the workflow of a pick and place robot. This sequence is highly precise and repeatable. The process begins with the robot receiving instructions from its control system. These instructions detail the task sequence, including where to pick up an object, where to place it, and the path to follow.

During operation, sensors and vision systems provide real-time feedback to the robot, ensuring accuracy and allowing for adjustments as needed. A combination of motors and actuators control the robot’s movements. They govern the motion of the arm and the operation of the end-effector.

Key Technologies Involved

- Role of AI and Machine Learning: Artificial Intelligence (AI) and Machine Learning (ML) play a critical role in enhancing the capabilities of pick and place robots. AI algorithms enable robots to learn from their environment and improve their performance over time. Machine learning, particularly deep learning, is used in vision systems to improve object recognition and handling. These technologies allow robots to adapt to variations in objects and environments, increasing their flexibility and efficiency.

- Robotics: The field of robotics provides the fundamental technologies that drive pick and place robots. This encompasses various aspects of the robot’s functionality. These include the mechanical design, such as arms and grippers, the electronic systems controlling movement (like motors and actuators), and the software algorithms governing their operation.

- Integration with Other Industrial Systems: Integration is key to maximizing the efficiency of pick and place robots. These robots are often part of a larger automated system, working in tandem with conveyor belts, sorting systems, and other robotic systems. Integration allows for seamless operation within the broader manufacturing or packaging process. For instance, in a production line, a pick and place robot can receive signals from upstream machinery. This ensures synchronization with the entire production process, allowing for seamless operation.

Also Read: AI Robot Captcha Becomes First Teacher

Key Components in Pick and Place Robotics

Breakdown of Essential Components

Pick and place robots are composed of several critical components that work together to execute precise and efficient operations. The main components include the robotic arm, end-effectors (such as grippers or vacuum systems), controllers, sensors, and the base or frame.

- Robotic Arm: The arm is the central component of the robot, providing the necessary range of motion. It is typically constructed with multiple joints and links, allowing for movement in various directions. The design of the arm can vary, with some robots featuring linear (straight-line) motion and others having more complex articulations for a wider range of movement.

- End-Effectors: The end-effector is the tool attached to the end of the robotic arm that physically interacts with the object. Common types of end-effectors include:

- Grippers: Mechanical devices that pinch or grasp objects. Grippers are designed to handle different materials, shapes, and sizes.

- Vacuum Systems: These use suction to pick up objects, ideal for handling delicate or irregularly shaped items.

- Controllers: The controller is the brain of the robot. It is a computerized unit that sends instructions to the robot about movement and operation. Controllers store the programming code and sequences necessary for the robot to perform its tasks.

- Sensors: Sensors provide the robot with information about its environment. This can include vision systems for object recognition and placement accuracy, as well as sensors for detecting the position and orientation of the robot and its components.

- Base/Frame: The base or frame of the robot provides structural support. It is designed to ensure stability and rigidity, allowing the robot to operate without vibrations or movements that could affect precision.

Role and Functionality of Each Component

- Robotic Arm: The robotic arm is responsible for the movement and positioning of the end-effector. Its design determines the robot’s reach, speed, and the weight of objects it can handle.

- End-Effectors: End-effectors directly handle the objects. Their design is crucial for ensuring secure and precise picking and placing of items. The choice between grippers and vacuum systems depends on specific application requirements, such as the nature of the objects being handled.

- Controllers: Controllers execute the programmed instructions, orchestrating the robot’s movements and actions. They process input from sensors and adjust the robot’s operations accordingly, ensuring accuracy and efficiency.

- Sensors: Sensors are key to the robot’s adaptability and precision. Vision sensors, for instance, enable the robot to identify the correct objects and their orientation, adjusting its actions as needed for accurate handling.

- Base/Frame: The base provides a stable platform for the robot’s operations. Its robustness is essential for maintaining the alignment and accuracy of the robotic arm, especially during high-speed movements or when handling heavy objects.

Also Read: Nvidia CEO Discusses AI and Self-Driving Opportunities

Classifications of Pick and Place Robots

Pick and place robots come in various designs, each suited to specific types of tasks based on their movement capabilities and structural configurations. The most common types include Cartesian, SCARA (Selective Compliance Articulated Robot Arm), Delta, and Articulated robots.

Different Types Based on Design and Functionality

- Cartesian Robots: These robots move in straight lines along the X, Y, and Z axes. They are known for their simple, rectangular design which offers high precision and straightforward programming.

- SCARA Robots: SCARA robots offer rotational movement along the horizontal axis and linear movement along the vertical axis. They are designed for tasks requiring a high degree of flexibility and speed in a plane.

- Delta Robots: Delta robots have a spider-like structure with parallel arms connected to a common base.They are exceptionally fast and suitable for tasks that require rapid and precise movements, typically in a small work envelope.

- Articulated Robots: These robots have rotary joints, allowing for movement similar to a human arm. They offer a high degree of flexibility and are capable of reaching around obstacles and working in confined spaces.

Comparative Analysis

- Cartesian Robots

- Pros: High precision, straightforward programming and operation, good for tasks involving linear movements.

- Cons: Limited flexibility in movement, relatively large footprint, and not well-suited for tasks requiring complex paths or obstacle avoidance.

- SCARA Robots

- Pros: High-speed operation, good for tasks requiring dexterity within a plane, compact design.

- Cons: Limited vertical movement, not suitable for tasks requiring complex three-dimensional movements.

- Delta Robots

- Pros: Extremely fast and precise, ideal for picking and placing at high speeds, compact vertical design.

- Cons: Limited working envelope, not suited for heavy loads or tasks requiring significant reach outside their immediate area.

- Articulated Robots

- Pros: High flexibility and reach, capable of complex movements and working in confined spaces, suitable for a wide range of tasks.

- Cons: More complex programming and control, typically larger and more expensive than other types.

Each type of pick and place robot has its unique strengths and limitations, making them suitable for different applications. The choice of robot depends on specific task requirements, including the nature of objects, required speed and precision, workspace configuration, and complexity of movements. Understanding these classifications helps in selecting the most appropriate robot for a given industrial application, ensuring efficiency and effectiveness in automated processes.

Enhancing Efficiency: The Benefits of Utilizing Pick and Place Robots

Improvement in Production Speed and Quality

- Increased Efficiency and Accuracy: Engineers design pick and place robots for high-speed operation with remarkable precision. They can consistently place items accurately, reducing the margin of error compared to manual handling. This capability is particularly beneficial in industries like electronics or pharmaceuticals, where precision is crucial.

- Consistent Output Quality: Robots, unlike human workers, are not affected by fatigue. They maintain a consistent level of performance throughout their operation. This consistency ensures that the quality of production remains uniform, which is essential in maintaining high-quality standards.

- Faster Production Cycles: The speed of pick and place robots significantly surpasses that of manual labor. This rapid operation translates into faster production cycles, enabling businesses to increase their throughput and meet higher production targets.

- Flexibility in Operations: Operators can quickly reprogram modern pick and place robots to perform different tasks. This flexibility allows for rapid adjustments in production lines to accommodate different products or changes in design, without the need for extensive downtime or retraining of staff.

Reduction in Labor Costs and Human Error

- Decreased Labor Costs: By automating repetitive and high-volume tasks, pick and place robots reduce the need for a large workforce. This reduction in labor can lead to significant cost savings, especially in high-wage economies.

- Minimized Human Error: Manual processes are prone to errors due to factors like fatigue, distraction, or lack of skill. Robots eliminate these variables, markedly reducing the rate of errors in production. This reliability is crucial in reducing waste and ensuring that products meet quality standards.

- Enhanced Workplace Safety: Pick and place robots can take over tasks that are hazardous or ergonomically challenging for human workers, such as handling heavy items or working in environments that are unsafe or uncomfortable. This not only reduces the risk of workplace injuries but also helps in complying with health and safety regulations.

- Optimized Workforce Utilization: Robots handle mundane and repetitive tasks, allowing the redeployment of human workers to roles that require critical thinking, problem-solving, and decision-making. This optimization of workforce utilization can lead to increased job satisfaction and productivity.

Real-World Applications: Where Pick and Place Robots Shine

Various Industries and Their Specific Uses

- Electronics Industry: In the electronics sector, precision and speed are paramount. Manufacturers use pick and place robots for assembling intricate electronic components like circuit boards. They place tiny parts with high precision. Their ability to handle delicate components quickly and accurately is crucial in maintaining the efficiency and quality of production lines.

- Automotive Industry: The automotive sector employs these robots for various tasks, including assembling small parts in engines and electronic systems. They also play a role in loading and unloading processes, handling heavy components with consistent precision. This enhances both the speed and safety of automotive manufacturing.

- Pharmaceuticals: In pharmaceutical manufacturing, pick and place robots handle sensitive tasks like filling drugs into containers, packaging, and labeling. Their use ensures high accuracy in dosages, maintains cleanliness standards, and enhances the overall efficiency of the packaging lines.

- Food and Beverage Industry: These robots are used for food sorting, packaging, and palletizing. They handle food items delicately and maintain hygiene standards, which is crucial in this industry. Their speed and efficiency help in meeting the high-demand cycles typical in food production.

- Consumer Goods: In consumer goods manufacturing, pick and place robots are instrumental in packaging and palletizing products. They can adapt to various product sizes and packaging types, ensuring flexibility and efficiency in production lines.

Case Studies

- Electronics Assembly: A leading electronics manufacturer implemented pick and place robots in its assembly line for mobile devices. The robots were tasked with placing microchips onto circuit boards. This implementation resulted in a 30% increase in production speed and a significant reduction in errors, leading to higher product quality and customer satisfaction.

- Automotive Parts Handling: An automotive company introduced pick and place robots for handling engine components. The robots were able to move heavy parts with precision and speed, reducing the production cycle time by 25% and minimizing the physical strain on workers.

- Pharmaceutical Packaging: A pharmaceutical company utilized pick and place robots to automate the process of bottling and packaging medications. The robots’ precise movements ensured accurate pill counts and proper labeling, complying with stringent industry regulations. This automation led to a 40% increase in packaging speed and a marked reduction in manual errors.

- Food Sorting and Packaging: A food processing plant integrated pick and place robots for sorting and packaging fruits. The robots were equipped with vision systems to sort fruits based on size and quality. This resulted in a more efficient sorting process, reduced food waste, and improved packaging speed, enhancing overall productivity.

In each of these cases, the introduction of pick and place robots led to improvements in production efficiency, product quality, and workplace safety. These examples underscore the transformative impact that these robots can have across various industries, optimizing processes and driving innovation in manufacturing and packaging operations.

Also Read: BYD Ships 5000 NEVs to Europe

Sector-Specific Utilization of Pick and Place Robots

Customized Solutions for Different Sectors

Pick and place robots have become integral in various industries, each with unique needs and challenges. These robots are highly adaptable, offering customized solutions tailored to the specific requirements of different sectors.

- Electronics Manufacturing: In electronics, components are often small and delicate. In this sector, manufacturers equip pick and place robots with precise and gentle grippers to handle tiny, fragile parts without causing damage. They also integrate these robots with advanced vision systems for accurate placement, a critical factor in assembling complex electronic devices.

- Automotive Assembly: The automotive industry requires handling of diverse components, from small electronics to large body parts. Robots used here are often more robust, capable of lifting heavy loads, and equipped with various end-effectors to handle different parts. They play a crucial role in streamlining assembly lines, from engine assembly to final car assembly processes.

- Pharmaceuticals and Healthcare: Accuracy and hygiene are paramount in this sector. Designers create robots to operate in sterile environments and handle products with extreme care to prevent contamination. These robots fill vials, package pills, and assemble medical devices, ensuring adherence to stringent health standards.

- Food and Beverage Processing: In food processing, hygiene and speed are critical. Pick and place robots used here are often made with materials that are easy to clean and maintain. They handle food products at high speeds, increasing throughput in processes like packaging, sorting, and bottling.

- Logistics and Warehousing: Efficiency and accuracy in sorting and packaging are vital in this sector. Businesses deploy robots for tasks such as order picking, packing, and palletizing. They often integrate them with warehouse management systems to streamline logistics operations.

Impact on Industry-Specific Processes

- Enhanced Precision and Quality Control: In industries like electronics and pharmaceuticals, the precision of pick and place robots leads to significant improvements in product quality and a reduction in manufacturing defects.

- Increased Production Throughput: In sectors like automotive and food processing, these robots drastically increase the speed of production lines, enabling companies to meet higher demand without sacrificing quality.

- Improved Worker Safety: By handling heavy or hazardous materials, robots reduce the risk of injuries in the workplace. This is particularly relevant in industries like automotive and chemicals.

- Cost Efficiency and Waste Reduction: In all sectors, the efficiency of robots leads to reduced labor costs and less material waste. This is due to their precision and the ability to operate continuously without fatigue.

- Flexibility in Production: The adaptability of these robots allows for quick changes in production, which is especially beneficial in industries facing frequent product changes or customization demands, such as consumer goods manufacturing.

Also Read: BYD Ships 5000 NEVs to Europe

Selecting the Optimal Pick and Place Robot for Your Operational Needs

Selecting the right pick and place robot is crucial for optimizing production efficiency and achieving business objectives. The decision involves evaluating several key factors to ensure that the robot’s capabilities align with the specific requirements of your operation.

Factors to Consider When Choosing a Robot

- Speed and Cycle Time: The speed of a robot is a critical factor, especially in high-volume production environments. Consider the cycle time – the total time a robot takes to complete one cycle of picking and placing an item. This should align with your production demands to ensure throughput targets are met.

- Precision and Accuracy: Depending on the application, the level of precision required can vary significantly. For tasks involving small or delicate components, such as in electronics manufacturing, a high degree of precision is necessary. Evaluate the robot’s repeatability and accuracy specifications to ensure they meet your needs.

- Load Capacity: This refers to the maximum weight the robot can handle. It’s essential to choose a robot with a load capacity that matches the weight of the items it will be handling, taking into account the weight of the end-effector as well.

- Reach and Working Envelope: The robot’s reach – the distance it can extend its arm – and its working envelope – the total area in which it can operate – should be sufficient for your workspace and the tasks it needs to perform.

- End-Effector Compatibility: The type of end-effector, such as a gripper or vacuum system, is crucial. It must be suitable for the specific characteristics of the items being handled, including material, size, and shape.

- Ease of Programming and Integration: Consider the ease of programming the robot and integrating it into your existing systems. User-friendly interfaces and compatibility with your current production line technology are important for seamless integration.

- Footprint and Space Requirements: Assess the physical space available in your facility. Some robots, like Cartesian robots, may require more floor space, while others, like Delta robots, have a smaller footprint but operate more vertically.

- Flexibility and Scalability: If your production needs are likely to change or expand, consider a robot with the flexibility to adapt to different tasks and the scalability to integrate with additional automation systems.

Matching Robot Capabilities with Business Requirements

- Understanding Business Objectives: Align the robot’s features with your overall business goals, whether it’s increasing production volume, enhancing product quality, reducing labor costs, or improving workplace safety.

- Cost-Benefit Analysis: Perform a cost-benefit analysis to determine the return on investment. This should include not only the initial cost of the robot but also long-term costs such as maintenance, operation, and potential upgrades.

- Consultation with Experts: It’s advisable to consult with robotics experts or vendors who can provide insights into the most suitable options based on your specific operational needs and constraints.

- Trials and Demonstrations: If possible, arrange for trials or demonstrations to see the robot in action. This can provide a clearer understanding of how the robot performs in real-world conditions and whether it meets your requirements.

Also Read: 2025: The Dawn of AI Agents?

Investment Analysis: Understanding the Cost of Pick and Place Robots

Investing in pick and place robots involves a comprehensive understanding of the costs associated with their acquisition, operation, and maintenance. It’s essential to conduct a detailed investment analysis to gauge the financial viability and long-term benefits of integrating these robotic systems into your operations.

Cost Breakdown

- Initial Investment: The initial cost includes the purchase price of the robot, which can vary significantly based on the type, capacity, and features of the robot. Additionally, expenses related to installation, programming, and integration into existing systems are part of the initial investment. For more sophisticated setups, costs for additional equipment like conveyor belts, vision systems, or customized end-effectors should also be considered.

- Maintenance Costs: Regular maintenance is crucial to ensure the longevity and optimal performance of the robot. This includes scheduled servicing, replacement of parts like grippers or sensors, and software updates. While modern robots are designed for durability, factor in potential repair costs for unexpected breakdowns.

- Operational Costs: These costs encompass the day-to-day expenses of running the robot. It includes energy consumption, which can vary based on the robot’s size and complexity, and expenses for consumables like lubricants. Additionally, consider the costs for personnel trained to operate and maintain the robot.

ROI Analysis

- Increased Productivity: The primary financial benefit of pick and place robots is increased productivity. By automating tasks, robots can operate at a consistent pace without breaks, significantly boosting output rates. This increase in production can lead to higher sales and revenue.

- Quality Improvement and Waste Reduction: Robots’ precision reduces errors and material waste, leading to savings in material costs and improved product quality. This can enhance the brand reputation and customer satisfaction, potentially increasing market share and pricing power.

- Labor Cost Savings: Automating repetitive tasks with robots can reduce the need for manual labor, leading to long-term savings in wages, benefits, and other labor-related costs. This is particularly significant in regions with high labor costs.

- Safety and Compliance: By taking over hazardous tasks, robots can reduce workplace accidents and associated costs, including healthcare, legal fees, and compensation. This also helps in compliance with safety regulations, potentially avoiding fines and legal issues.

- Long-Term Financial Benefits: When calculating ROI, consider the long-term benefits. Although the upfront costs can be substantial, the efficiencies and savings gained over time can make the investment financially worthwhile. The payback period varies but can be as short as a couple of years, depending on the application.

Conducting a thorough investment analysis requires not only an understanding of the costs but also an assessment of the qualitative benefits, such as improved worker satisfaction and positioning for future technological advancements. By carefully analyzing these factors, businesses can make informed decisions about integrating pick and place robots into their operations, ensuring that the investment aligns with their long-term strategic goals.

Also Read: 6 hours of robots!

Task Spectrum: The Versatility of Pick and Place Robots in Action

Range of Tasks and Capabilities

Pick and place robots are known for their versatility, capable of performing a broad spectrum of tasks across various industries. Their design and advanced technology enable them to handle a wide range of operational demands.

- Assembly Operations: These robots are adept at assembling components in manufacturing processes, especially where precision and speed are essential. They can assemble everything from small electronic parts to larger mechanical assemblies.

- Packaging and Palletizing: In the packaging industry, operators use these robots to pack products into boxes, arrange items on pallets for shipping, and prepare goods for distribution. The robots’ precision ensures efficient and safe packing of products.

- Sorting and Inspection: Equipped with vision systems, pick and place robots can sort items based on size, color, shape, or barcodes. They are also used for quality inspection tasks, identifying defects and ensuring products meet quality standards.

- Machine Tending: They can load and unload parts from machines, such as CNC machines and injection molding machines, enhancing the efficiency of manufacturing processes.

- Material Handling and Transfer: Pick and place robots efficiently transfer materials between different stages of a production line, reducing manual handling and improving process flow.

- Food Processing: In the food industry, these robots handle tasks like sorting food items, placing them in containers, and food packaging, maintaining hygiene and handling food items delicately.

Flexibility in Different Scenarios

The adaptability of pick and place robots in various operational contexts is a key factor in their widespread adoption.

- Customization for Specific Needs: Manufacturers can customize robots with various end-effectors and programming to suit specific tasks. This customization allows them to handle anything from delicate electronics to heavy automotive parts.

- Integration with Other Technologies: Manufacturers can integrate these robots with other automation technologies, such as conveyor belts, inspection systems, and advanced software. This integration enables synchronized operation within a production line.

- Scalability in Operations: As business needs evolve, operators can scale up or reconfigure these robots. They can adjust them to handle increased volumes or changes in production requirements.

- Adaptation to Changing Environments: With advanced sensors and AI, pick and place robots can adapt to changes in their working environment, such as variations in product types or production layouts.

- Collaboration with Human Workers: In scenarios where human expertise is essential, pick and place robots can work alongside human workers, enhancing productivity while maintaining safety.

The task spectrum of pick and place robots illustrates their role as a key enabler of efficiency and flexibility in modern manufacturing and processing industries. Their ability to adapt to a wide range of tasks and integrate seamlessly into various operational contexts makes them invaluable assets in today’s rapidly evolving industrial landscape.

Also Read: Federal Regulators Back Musk, OpenAI Lawsuit

Future Directions in Pick and Place Robotics: Trends and Innovations

The field of pick and place robotics is continually evolving, driven by advancements in technology and changing market demands. Anticipating future trends and innovations is key for businesses looking to stay competitive and adapt to emerging opportunities.

Emerging Technologies

- Advanced AI and Machine Learning: Future pick and place robots are expected to incorporate more advanced AI and machine learning algorithms. This will enable them to learn and improve over time, increasing their efficiency, adaptability, and ability to handle complex tasks.

- Enhanced Vision Systems: Developments in vision technology will likely lead to more sophisticated and accurate object recognition capabilities. This could include improved 3D vision and the ability to recognize a wider array of materials and shapes, enhancing versatility in various applications.

- Greater Integration with IoT: The integration of robots with the Internet of Things (IoT) will enable better connectivity and data exchange between different systems. This interconnectedness can lead to more intelligent and responsive robotic systems, capable of adapting to real-time changes in the production environment.

- Collaborative Robots (Cobots): The trend towards collaborative robots will continue, with enhancements in safety features and human-robot interaction. These cobots will be more intuitive to work with, allowing for more flexible and efficient human-robot collaboration in various settings.

- Miniaturization and Mobility: There is a growing trend towards smaller, more mobile pick and place robots. Compact units can be easily moved and reconfigured for various tasks, making them ideal for small and medium-sized enterprises or flexible production lines.

Predicted Market Trends

- Increased Adoption Across Industries: Pick and place robots will likely see increased adoption in healthcare, agriculture, and retail, beyond traditional manufacturing. This trend is driven by their versatility and decreasing costs.

- Focus on Customization and Flexibility: As businesses seek solutions tailored to their specific needs, there will be a greater emphasis on customization and flexibility in robotic solutions. This includes modular designs that can be easily adapted or upgraded.

- Sustainability and Energy Efficiency: With growing awareness of environmental issues, future developments in robotics will likely include a focus on energy efficiency and sustainability, both in terms of the materials used in manufacturing robots and their operational energy consumption.

- Emergence of Robotics as a Service (RaaS): The RaaS model, where robots are leased rather than purchased outright, is expected to grow. This model offers businesses a cost-effective way to access the latest robotic technologies without a significant initial investment.

- Advancements in Robot Software: The software that powers these robots will become more sophisticated, offering better user interfaces, easier programming, and enhanced integration capabilities with other digital systems.

Also Read: Autonomous Cars: How do Self-Driving Cars Actually Work?

Conclusions: Summarizing the Impact and Potential of Pick and Place Robots

The integration of pick and place robots into various industrial sectors marks a significant leap in the pursuit of efficiency, precision, and automation. These robots have revolutionized the way tasks are performed in manufacturing and packaging, bringing about transformative changes in productivity and quality control. As we look toward the future, the potential of these robotic systems continues to expand, promising even more profound impacts on industrial processes.

The Overarching Benefits

- Enhanced Efficiency and Productivity: One of the most significant impacts of pick and place robots is the remarkable increase in efficiency and productivity they bring to production lines. Their ability to operate at high speeds, with consistent accuracy, translates into faster production cycles and higher throughput.

- Improved Quality and Precision: The precision of these robots in handling and placing objects reduces errors and defects in products, ensuring higher quality standards. This is particularly crucial in industries where precision is non-negotiable, such as electronics and pharmaceuticals.

- Reduction in Labor Costs and Workplace Injuries: By automating repetitive and physically demanding tasks, pick and place robots reduce the reliance on manual labor and minimize the risk of workplace injuries. This not only leads to cost savings but also promotes a safer work environment.

- Adaptability and Flexibility: Their versatility enables reprogramming and outfitting pick and place robots with various end-effectors. This enables their use in a wide range of applications. This adaptability is a key factor in their widespread adoption across different industries.

Future Outlook

- Continued Technological Advancements: As technology evolves, especially in AI, machine learning, and vision systems, experts anticipate pick and place robots will become even more efficient, intelligent, and versatile. These advancements will enable them to handle more complex tasks and adapt more readily to changing operational needs.

- Expansion into New Sectors: The benefits of robotic automation are set to extend beyond traditional manufacturing and packaging industries. Sectors like healthcare, agriculture, and retail are beginning to explore the potential of these robots, indicating a broader scope of application in the future.

- Increased Focus on Customization and Collaboration: The trend towards more customized and collaborative robotic solutions is likely to grow. Manufacturers will develop robots that can be easily customized for specific tasks and environments. They will also enhance cobots’ capabilities to work more effectively alongside human workers.

- Sustainability and Environmental Considerations: Future developments in pick and place robotics are likely to incorporate sustainability considerations, focusing on energy-efficient operations and the use of environmentally friendly materials.

In conclusion, pick and place robots represent a pivotal innovation in industrial automation, offering a multitude of benefits in terms of efficiency, quality, safety, and flexibility. As we move forward, the ongoing advancements in technology and expansion into new markets hint at an even greater role for these robots in shaping the future of industrial processes. The potential of pick and place robotics to drive efficiency, innovation, and growth across various sectors remains vast and largely untapped, holding promise for continued advancements and applications in the years to come.

Also Read: Learning Python in 2025: A Fresh Start

AI-Powered Intelligence: Amplifying Robotic Capabilities:

Vision Systems: Cameras coupled with sophisticated image recognition algorithms allow robots to identify objects based on size, shape, color, and even intricate markings. This opens doors for bin picking and intricate assembly tasks.

Machine Learning: Algorithms learn from experience, enabling robots to adapt to variations in object placement and even predict potential issues. This enhances efficiency and reduces downtime.

Collaborative Robots (Cobots): Smaller, lighter robots equipped with advanced safety features, cobots work alongside human operators, offering an extra pair of tireless hands for delicate tasks.

As the march of technology continues, pick and place robots will undoubtedly become even more intelligent and adaptive. From handling exotic materials in space exploration to performing microsurgery in medicine, the possibilities seem limitless. So, the next time you encounter a meticulously placed circuit board or a flawlessly packaged product, remember the intricate dance of engineering, history, and AI that powered its journey.

Also Read: Robotics and Manufacturing.

Addressing Common Queries Regarding Pick and Place Robots

FAQs

- What tasks are pick and place robots typically used for?

- Manufacturers and packagers primarily use pick and place robots for repetitive tasks such as assembling parts, sorting products, packing items into boxes, and handling materials in production lines.

- How do pick and place robots differ from other industrial robots?

- Designers specifically create pick and place robots for high-speed, precise handling, and placement of objects, distinguishing them from other types of industrial robots. Typically more compact and faster, these robots specialize in specific tasks.

- Can pick and place robots be reprogrammed for different tasks?

- Indeed, operators can reprogram most modern pick and place robots to perform various tasks, making them highly flexible. This allows for adaptability in dynamic production environments.

- What is the average lifespan of a pick and place robot?

- The lifespan varies based on usage and maintenance, but on average, a well-maintained pick and place robot can operate for 10 to 15 years.

- Are pick and place robots cost-effective for small businesses?

- With advancements in technology, the cost of these robots has become more accessible for small businesses. The return on investment should be evaluated based on the specific needs and scale of the business.

Expert Opinions

- On the Future of Automation: Industry experts often emphasize that pick and place robots are a stepping stone towards more advanced automation. They foresee a future in which these robots will integrate with AI and IoT, leading to even greater efficiencies.

- Regarding Workforce Impact: Experts also discuss the impact of automation on the workforce. While robots take over repetitive tasks, they see a shift in the workforce towards more skilled positions for operating, maintaining, and programming these robots.

- On Customization and Flexibility: Leaders in robotic manufacturing stress the importance of customization. Advisors recommend that businesses seek solutions tailored to their specific operational needs. This ensures that the robots can adapt to changes in production demands.

- Concerning Safety and Compliance: Safety is a recurring theme among experts. They highlight that with the correct safety measures and programming, pick and place robots can significantly reduce workplace accidents and ensure compliance with safety standards.

- Advice on Investment: Financial advisors in the industry often suggest a thorough cost-benefit analysis before investing in pick and place robots. They recommend considering not only the immediate operational improvements but also the long-term strategic benefits of integrating such technologies.

Addressing these common queries and considering expert opinions can provide valuable insights for businesses contemplating the integration of pick and place robots into their operations. These perspectives highlight the importance of careful planning, customization, and consideration of long-term impacts on efficiency, workforce dynamics, and safety.

Also Read: Replit CEO Prioritizes AI Over Professional Coders

References and Further Reading

To gain a comprehensive understanding of pick and place robots and to keep up with the latest trends and developments in this field, you can consult a variety of academic and industry sources. Below is a list of recommended references that provide comprehensive information and insights:

Academic Journals and Papers:

- Robotics and Computer-Integrated Manufacturing: This journal offers research papers on the latest developments in robotics, including studies specific to pick and place robots.

- The International Journal of Advanced Manufacturing Technology: Provides articles on advanced manufacturing technologies, with some focusing on automation and robotics.

- IEEE Transactions on Automation Science and Engineering: Features research on automation engineering, including robotics applications in various industries.

- Journal of Manufacturing Systems: Offers insights into manufacturing systems with a focus on automation and robotics technologies.

- Robotics and Autonomous Systems: This journal covers various aspects of robotics, including design, applications, and technology advancements.

Books:

- “Industrial Robotics: Technology, Programming, and Applications” by Mikell P. Groover: A comprehensive guide to industrial robotics, including chapters on pick and place automation.

- “Robotics and Automation Handbook” by Thomas R. Kurfess: Provides an overview of robotics technology, including applications in material handling and manufacturing.

- “Introduction to Autonomous Robots” by Nikolaus Correll, Bradley Hayes, and Nikolaus Correll: Offers foundational knowledge in robotics, useful for understanding the principles behind pick and place robots.

Industry Reports and Whitepapers:

- Robotic Industries Association (RIA) Reports: Offers industry reports on the state of robotics, including market trends and technology advancements.

- International Federation of Robotics (IFR) World Robotics Reports: Provides annual reports on robotics statistics and market analysis, including the use of pick and place robots in various sectors.

- McKinsey & Company Reports on Automation and Robotics: Features insights into the impact of robotics and automation on industries and economies.

Online Resources and Websites:

- Robotics Online: Hosted by the Robotic Industries Association, this website provides articles, case studies, and news related to industrial robotics.

- IEEE Robotics and Automation Society: Offers resources, publications, and educational materials on robotics and automation.

- The Robot Report: A website offering news, information, and analysis on the global robotics industry.

Conferences and Seminars:

- International Conference on Robotics and Automation (ICRA): An annual event that presents the latest research and developments in robotics.

- Automate Show: Features exhibits and seminars on automation technology, including robotics applications.

These sources provide valuable information for researchers, industry professionals, and anyone interested in the field of robotics. They offer a blend of theoretical knowledge, practical insights, and updates on cutting-edge advancements in pick and place robot technology.